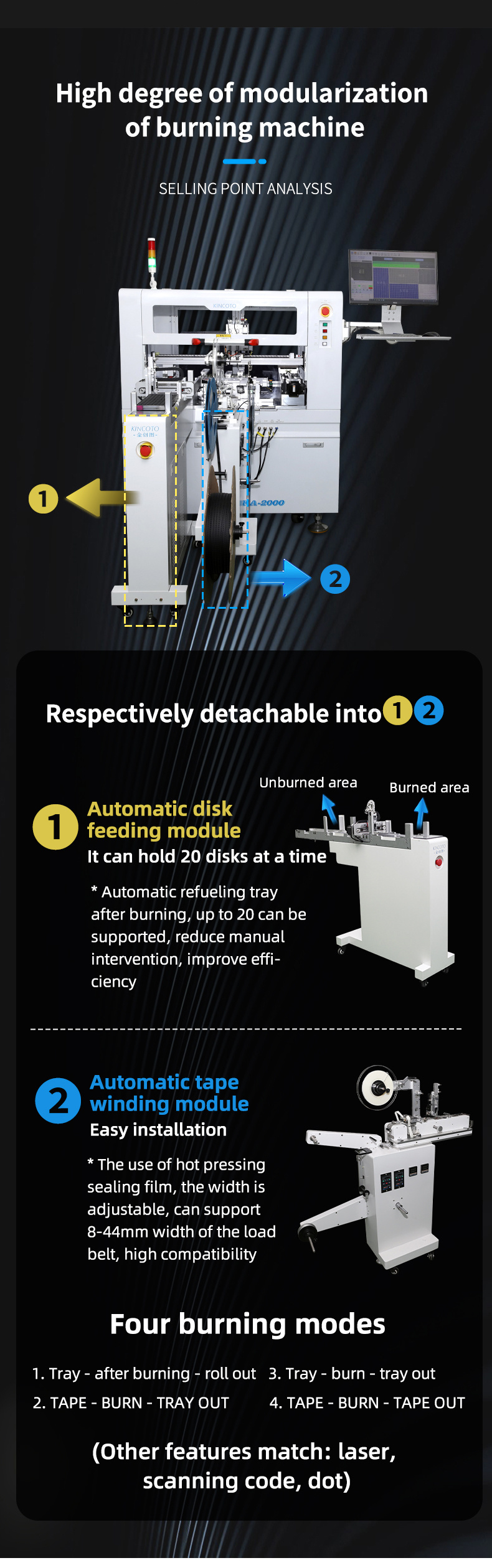

KA2000 TRAY AND TAPE INTEGRATED PROGRAMMING MACHINE

- Description

- Feature

- Parameter

-

Output up to 2000-2500 units per hour

Compatible for tray in/out, tape in/out, tray in/tape out, tape in/tray out and laser or ink maker

Great for long chip programming time and medium to high capacity programming

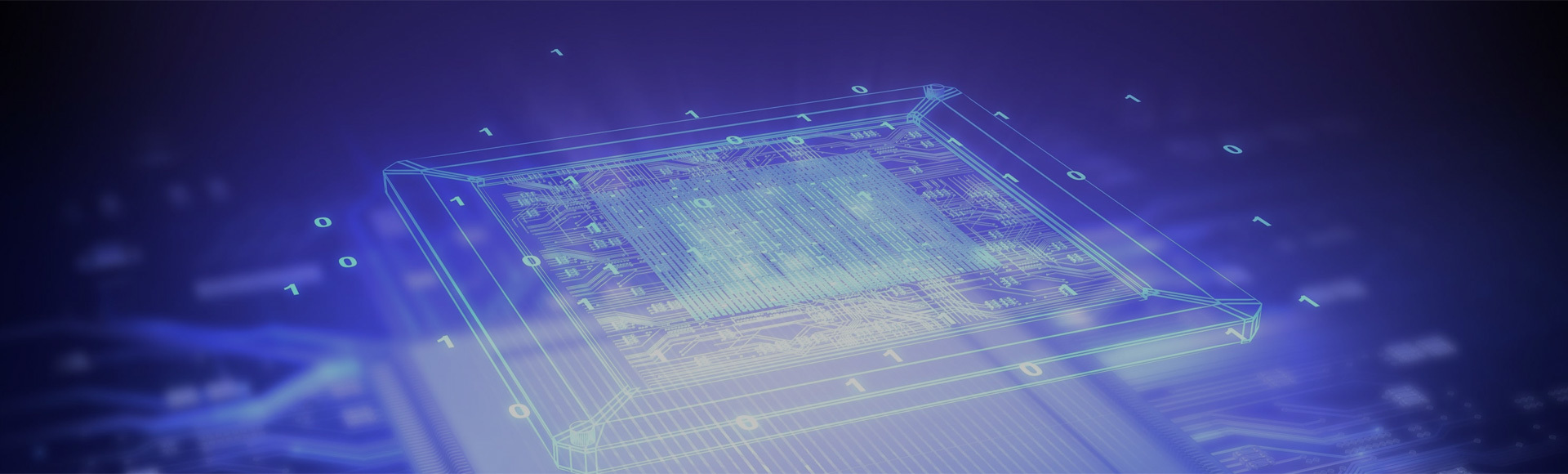

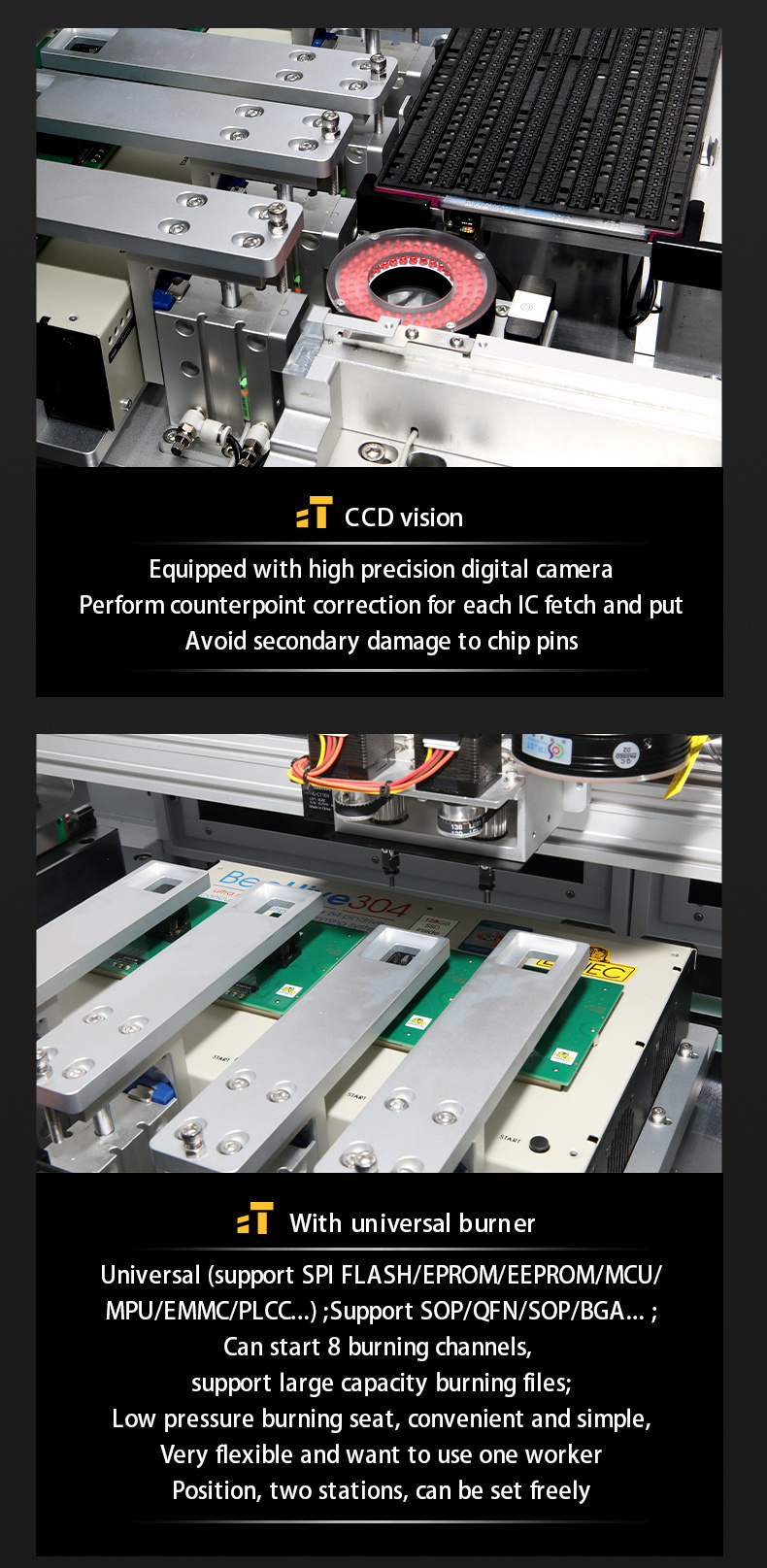

Equipped with an external programmer to realize offline programming

Automatic disk feeding device: tray in/out (up to 20 trays)

Automatic tape feeding device: tape in/out (Standard 12-16mm, optional 8-32mm、4-44mm feeder

-

Transmission control system

① Equipped with imported servo and grinding grade lead screw for X-Y-Z axis transmission, making the operation stable, accurate and fast;

② Rotating 2 suction pens close to the structure of the mounter, which is the key structure in terms of efficiency;

③Running accuracy ±0.03mm;

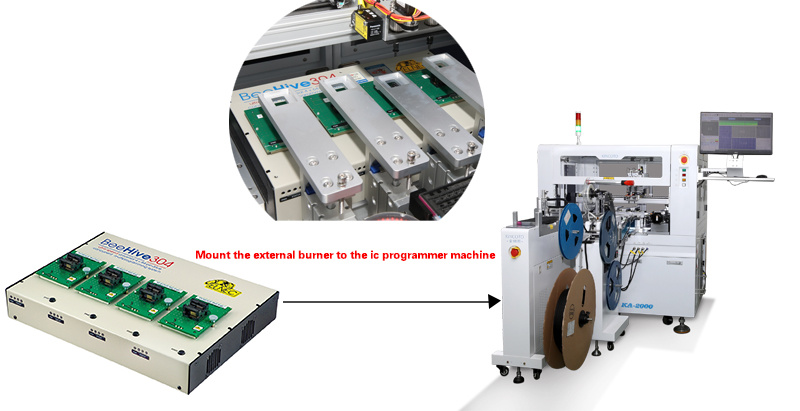

visual system

① Equipped with a high-precision digital camera to correct the alignment of each IC pick-and-place to avoid secondary damage to the chip pins;...

Feeding and discharging device system

①Fully automatic tray feeding (20 trays of IC can be fed at one time);

②Automatic tape feeding (Standard 12-16mm, optional 8-32mm、4-44mm feeder);

③Trays can be arbitrarily selected for discharging (20 trays can be produced at one time) and tapes;

④Standard refilling tray (can ensure that the OK material is fully discharged);

-

Output efficiency 2000UPH Overall size 1750*1850*1710 Supports ic packing QFP/QFN/SOP/BGA Programming station 8 stations Take-and-place device 2 vacuum nozzles Monitor 19 "LED Pick and place accuracy 0.03MM Control mode Embedded control panel Programming mode Lower pressure socket Positioning system CCD(optional) Tray loading and unloading Automatic disk feeding device up to 20 disks Tape feed Standard 12-16MM optional 8-32MM feida Tape discharge Adjustalble automatic hot pressing film sealing device Input voltage AC220/50HZ Power 1.3KW Air source 0.4-0.6MPA Total weight 620kg

Related products

There is currently no information to display