AUTOMATIC TAPE PROGRAMMING MACHINE KA42-2000

- Description

- Feature

- Parameter

-

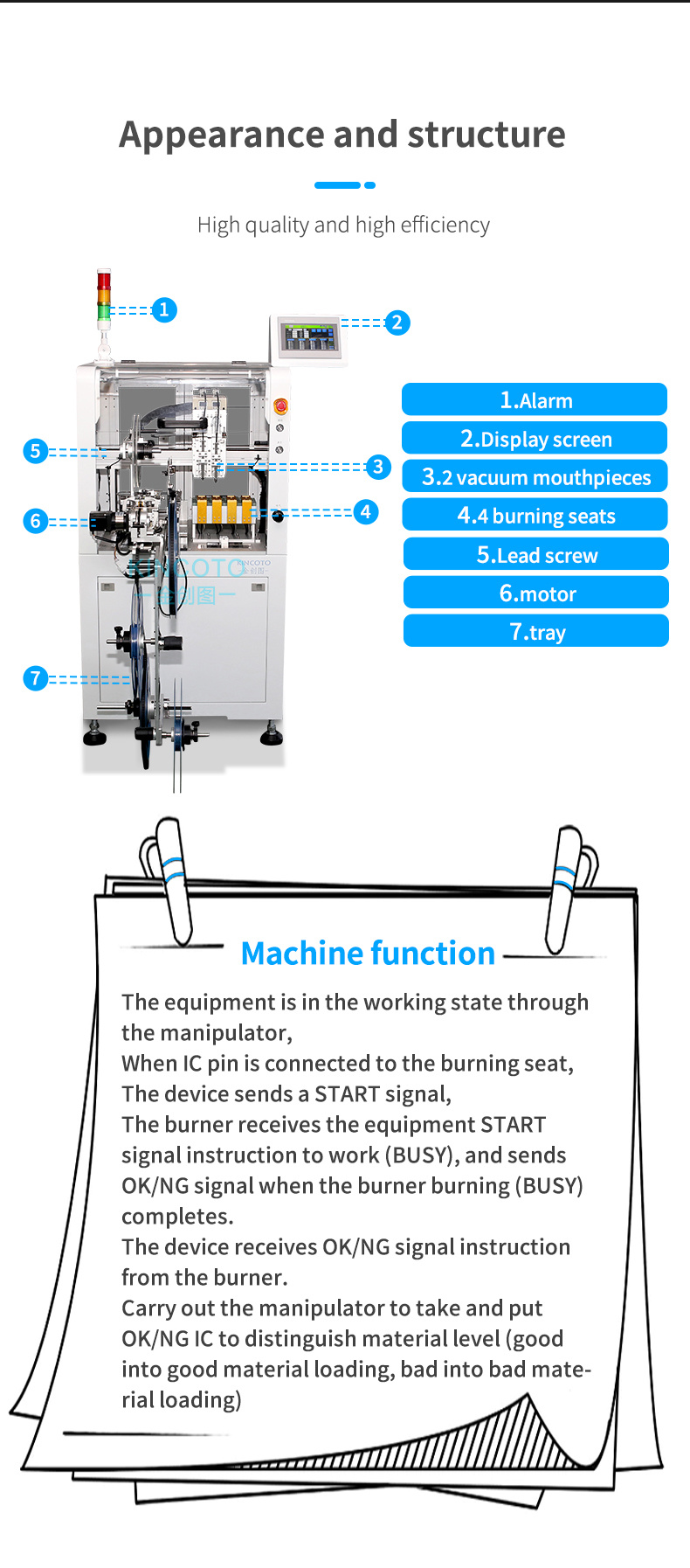

KA42-2000 supports IC material packaging as tape, realizes tape in and out, automatically packs after programming is completed, and automatically distinguishes between 0K and NG IC automatic programming machines.

-

x, z axis manipulator, double nozzle:

Replace manual single IC pick-up and placement:

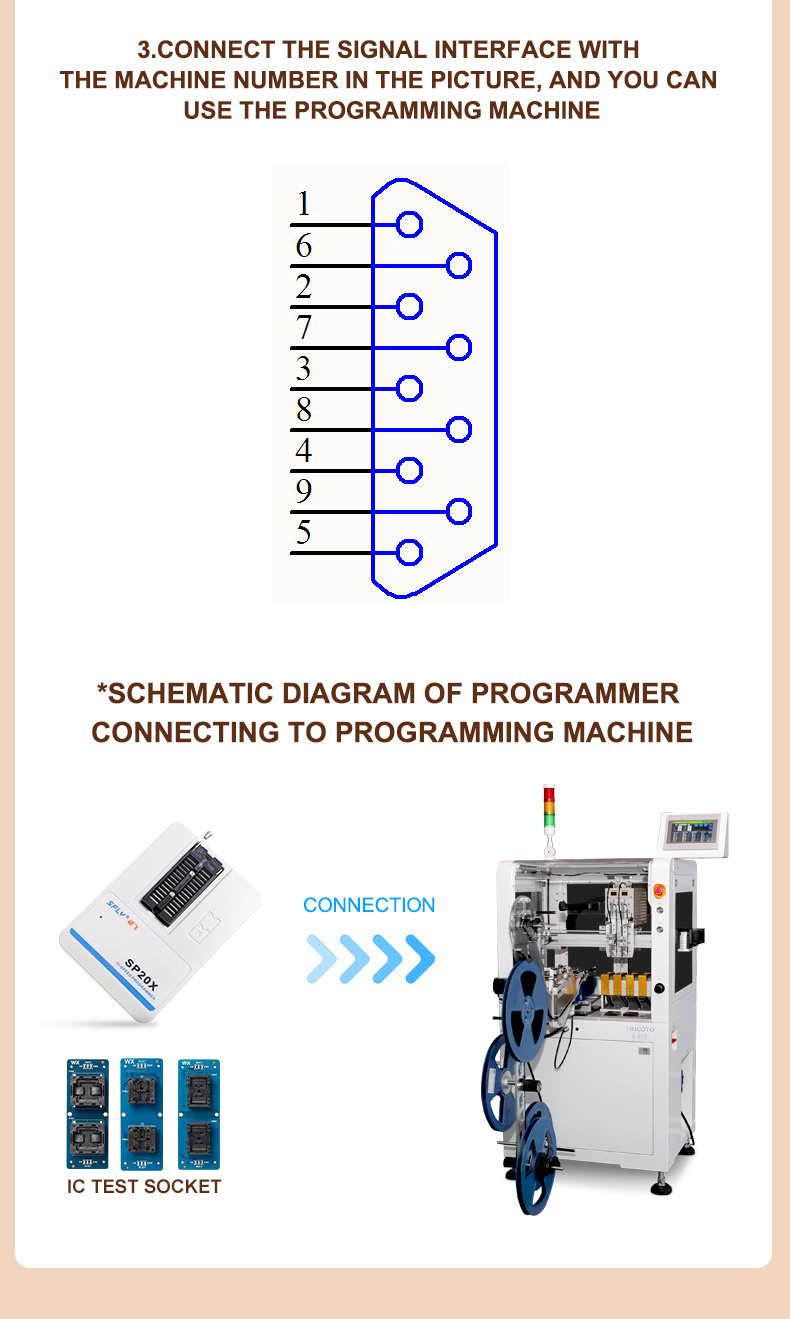

One-pick-and-place suction pen designSignal communication connection

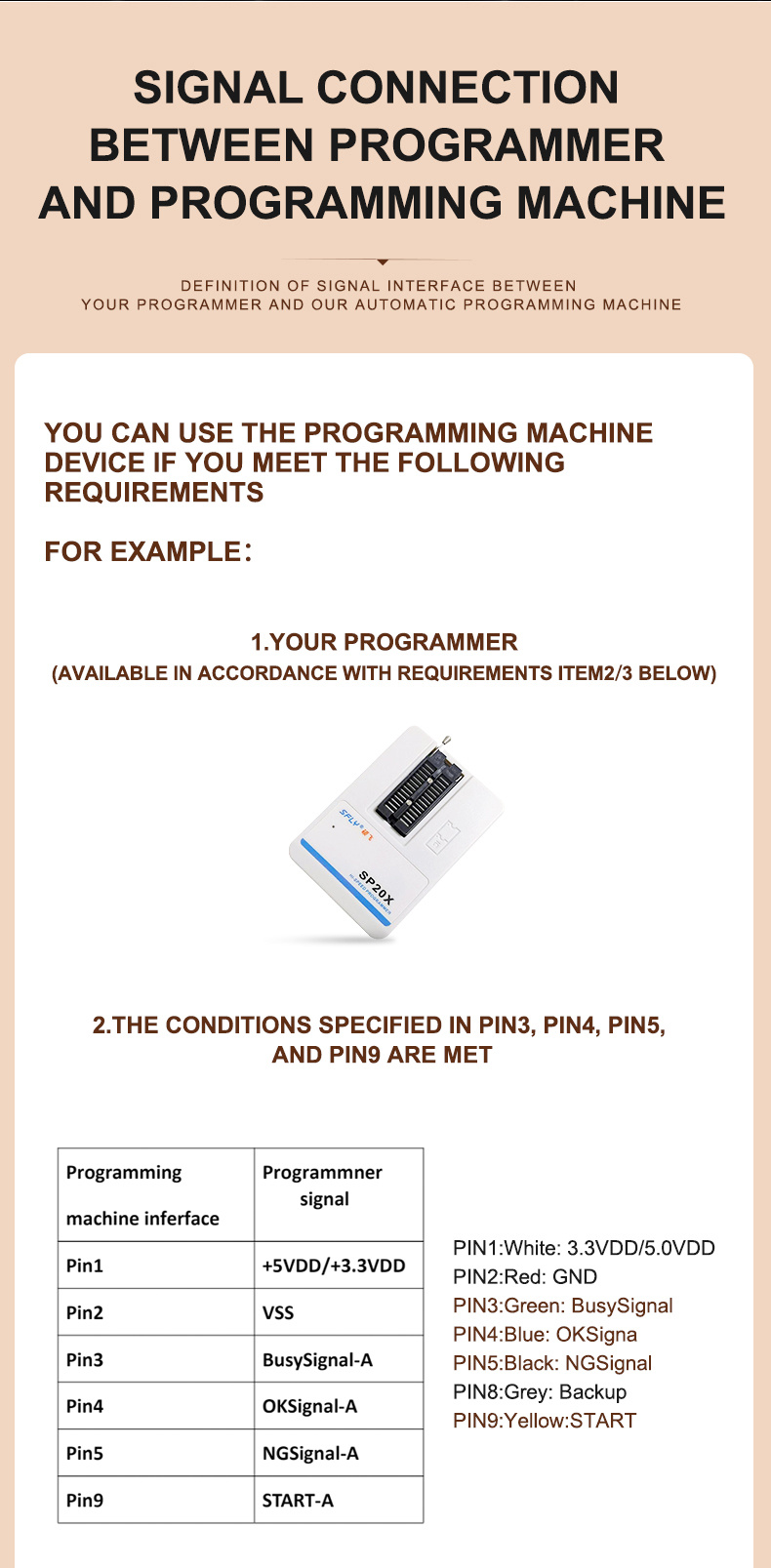

Support offline programmer (subject to the actual function!);

When programming is completed, automatically distinguish between 0K and NG ICs and place them to the corresponding position coordinates that have been setIn and out mateial packaging support:

Support tape in and out;

Unloaded can be recycled and reusedProgramming station:

1-4 programming stations can be customized to start;

Different packages can be replaced with corresponding programming sockets,

Different packages can be pre-installed in advance according to needs, which is more convenient to use.UPH output:

The programming completion time of the programming file is within 4 seconds, and the efficiency is 2000 pieces/hour;

Reference. The efficiency of general MCU is about 1800 pieces/hour;

The programming time is greater than 4 seconds, and the efficiency will be relatively reducedData and formula

You can customize the programming OK and feeding quantity, NG continuous alarm limit quantity, automatically record other production quantities, and customize the programming formula to facilitate the replacement of programming with different contentsOptional ink dotting mechanism supports automatic roll-out IC mark dotting

Optional laser printing and support automatic roll-out IC mark printing

-

Output efficiency 2000UPH Overall size 870*1170*1630mm (length x width x height) Support IC packaging QFN,SOP,SSOP,TSSOP,SON,QFP... Programming station Four stations Take-adn-place device Vacuum nozzle*2 Feeding device Standard 12-16mm, optional 8-32mm feeder programming mode Embedded control panel Discharge device Adjustable automatic heat-pressing film sealing device User Interface 7” LCD control method Embedded control panel Input voltage AC220/50ZHz power 0.25KW weight 140KG Gas source 0.4-0.6MPA

Related products